-

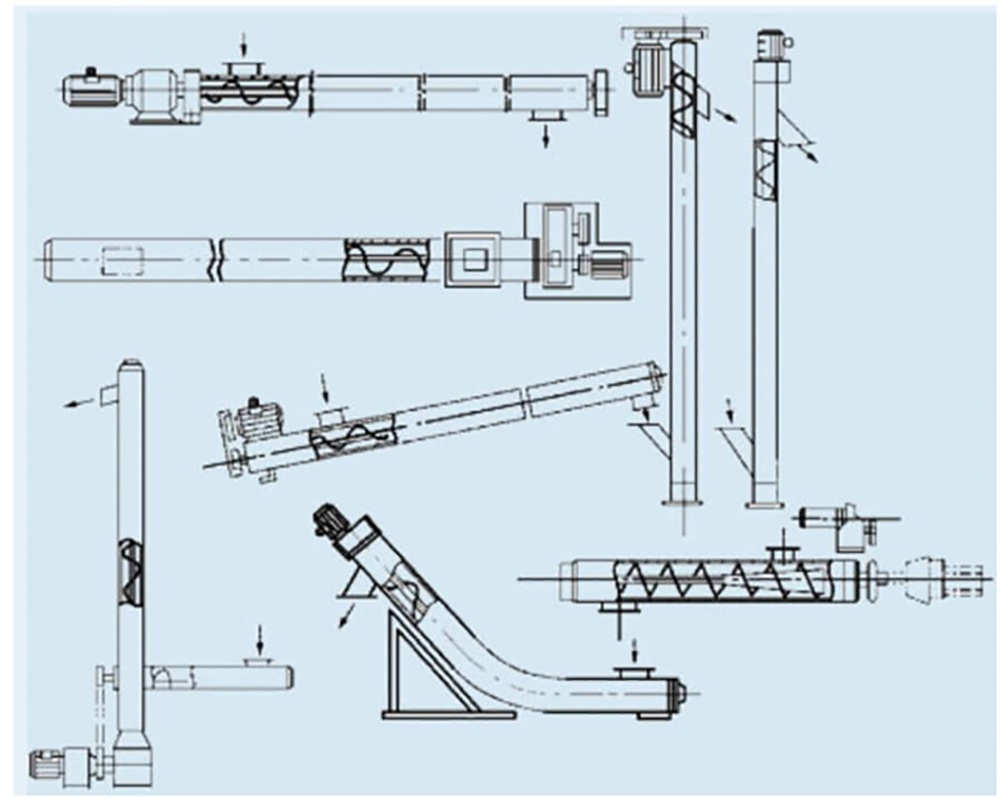

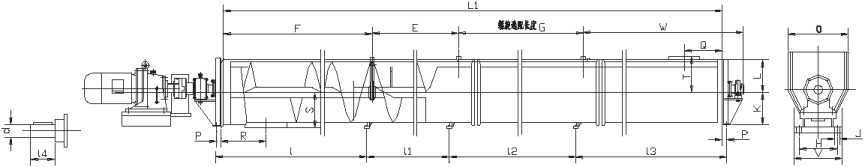

Description & Overall Dimensions Drawing

LS screw conveyor is designed according to ISO1050 standard,Its hanging bearing has roll and slide structure with sealing device,it has clean device in the discharge port,the inlet and outlet are setuping flexibly,there are low noise, strong adaptability and operation and maintenance smoothly. The sealed parts is made in nylon and PTEF resins which has small resistance, good sealing and wear resistance.

LS Screw Conveyor/Spiral conveyor/Helix conveyor/Auger conveyor

description1

Zipper closure

1/5 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the

body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them

in

place during workout

Features

The LS screw conveyor diameter is 100-1250mm, there are 11 models, the length is 4-70meter,each 0.5meter is a grade,the drive is XWD cycloidal pin wheel reducer,it has single drive (C1)system and double drive (C2)system. we consider C1 way if length is under 35 meter.

Screw conveyor is used in many industries,such as building materials,chemical engineering.coal, grain and oil, fodder. It is suitable for horizontal or inclined conveyor powdery, granulousand small block material, such as grain, dinas, coal, flour, cement, chemical fertilizer and soon. It cant convey material which is easy to metamorphic, sticky, agglomeration; Using

temperature of environment is -20~50°C,conveying material temperature is s200°℃.

temperature of environment is -20~50°C,conveying material temperature is s200°℃.

Application

- Food Processing

- Pharmaceutical

- Powder and energy

- Petrochemical

- Chemicals

- Mining and minerals

- Feed processing

- Plastic

Drawing

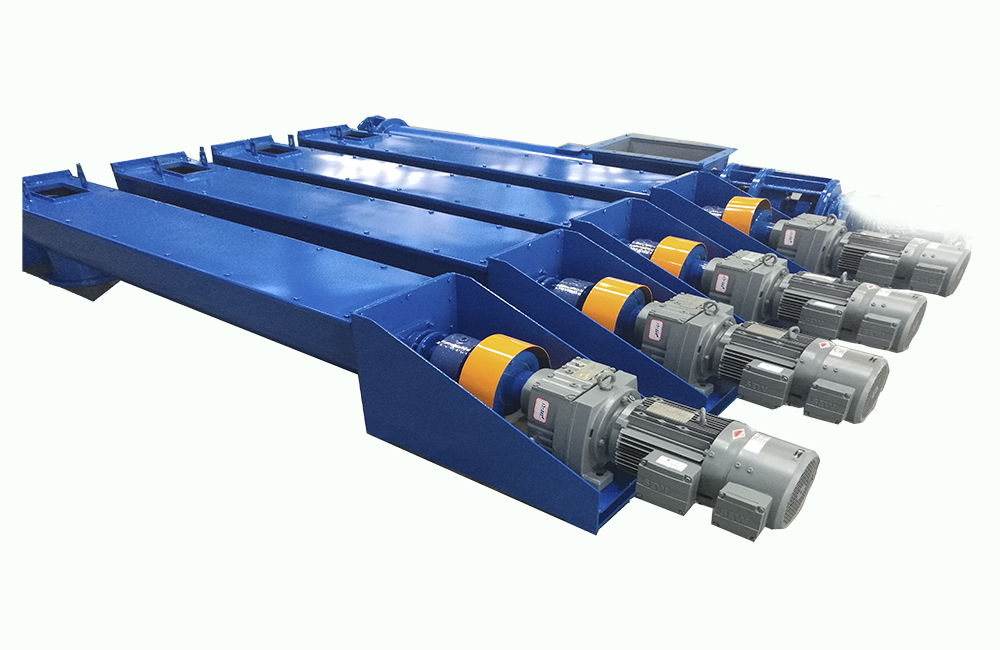

Product Display

-

lnclined screw conveyor

-

Inclined screw conveyor

-

LS screw conveyor

-

Cooling screw conveyor

-

Tube screw conveyor

-

Tube screw conveyor

-

Stainless steel screw conveyor

-

Shaftless screw conveyor

-

Double screw conveyor

-

SSC screw conveyor

-

Screw auger

-

Shaftless screw blade

Main Parameters

|

Model |

LS100 |

LS160 |

LS200 |

LS250 |

LS315 |

LS400 |

LS500 |

LS630 |

LS800 |

LS1000 |

LS1250 |

|

screwdiameter(mm) |

100 |

160 |

200 |

250 |

315 |

400 |

500 |

630 |

800 |

1000 |

1250 |

|

pitch ofscrew(mm) |

100 |

160 |

200 |

250 |

315 |

355 |

400 |

450 |

500 |

560 |

630 |

|

speed(r/min) |

140 |

112 |

100 |

90 |

71 |

71 |

63 |

50 |

40 |

32 |

25 |

|

capacity(M³/h ) |

2.2 |

7 |

13 |

22 |

49 |

62 |

98 |

140 |

200 |

280 |

380 |

|

speed(r/min) |

112 |

90 |

80 |

71 |

56 |

56 |

50 |

50 |

32 |

25 |

20 |

|

capacity(M³/h ) |

1.7 |

6 |

10 |

18 |

39 |

49 |

78 |

112 |

160 |

220 |

306 |

|

speed(r/min) |

90 |

71 |

63 |

56 |

45 |

45 |

40 |

32 |

25 |

20 |

16 |

|

capacity(M³/h ) |

1.4 |

5 |

8 |

14 |

29 |

39 |

62 |

90 |

126 |

176 |

245 |

Main Dimensions

|

Model |

F |

E |

W |

L |

L1 |

L2 |

screw length G |

foot size L2 |

Q |

Y |

||||

|

LS100 |

2500 |

2500 |

2500 |

2480 |

2500 |

2640 |

1500 |

2000 |

2500 |

1500 |

2000 |

2500 |

180 |

180 |

|

LS160 |

2500 |

2500 |

2500 |

24B0 |

2500 |

2640 |

1500 |

2000 |

2500 |

1500 |

2000 |

2500 |

220 |

180 |

|

LS200 |

2500 |

2500 |

2500 |

2480 |

2500 |

2640 |

1500 |

2000 |

2500 |

1500 |

2000 |

2500 |

225 |

180 |

|

LS250 |

3000 |

3000 |

3000 |

2980 |

3000 |

3140 |

1500 |

2000 |

2500 |

1500 |

2000 |

2500 |

250 |

200 |

|

LS315 |

3000 |

3000 |

3000 |

2980 |

3000 |

3140 |

1500 |

2000 |

2500 |

1500 |

2000 |

2500 |

330 |

220 |

|

LS400 |

3000 |

3000 |

3000 |

2980 |

3000 |

3140 |

1500 |

2000 |

2500 |

1500 |

2000 |

2500 |

350 |

227 |

|

LS500 |

3000 |

3000 |

3000 |

3000 |

3000 |

3160 |

2000 |

2500 |

3500 |

2000 |

2500 |

3500 |

400 |

250 |

|

LS630 |

3000 |

3000 |

3000 |

3000 |

3000 |

3160 |

2000 |

2500 |

3500 |

2000 |

2500 |

3500 |

450 |

300 |

|

LS800 |

3000 |

3000 |

3000 |

3000 |

3000 |

3160 |

2000 |

2500 |

3500 |

2000 |

2500 |

3500 |

550 |

340 |

|

LS1000 |

3000 |

3000 |

3000 |

3000 |

3000 |

3160 |

2000 |

2500 |

3500 |

2000 |

2500 |

3500 |

650 |

360 |

|

LS1250 |

3000 |

3000 |

3000 |

3000 |

3000 |

3160 |

2000 |

2500 |

3500 |

2000 |

2500 |

3500 |

800 |

380 |

|

Model |

L |

K |

R |

S |

E |

0 |

H |

V |

J |

E |

P |

T |

D |

I4 |

|

LS100 |

63 |

112 |

180 |

112 |

40 |

178 |

120 |

160 |

14 |

208 |

60 |

163 |

30 |

58 |

|

LS160 |

90 |

150 |

200 |

150 |

50 |

266 |

120 |

160 |

14 |

240 |

60 |

190 |

35 |

58 |

|

LS200 |

112 |

180 |

225 |

180 |

60 |

320 |

160 |

200 |

14 |

280 |

60 |

212 |

40 |

82 |

|

LS250 |

140 |

224 |

250 |

224 |

70 |

370 |

200 |

250 |

16 |

285 |

60 |

240 |

50 |

82 |

|

LS315 |

180 |

280 |

390 |

250 |

80 |

443 |

300 |

350 |

20 |

320 |

60 |

340 |

60 |

105 |

|

LS400 |

224 |

355 |

390 |

280 |

90 |

533 |

320 |

400 |

24 |

395 |

60 |

384 |

80 |

130 |

|

LS500 |

280 |

400 |

400 |

340 |

105 |

653 |

400 |

500 |

24 |

397.5 |

80 |

440 |

90 |

130 |

|

LS630 |

355 |

500 |

450 |

420 |

120 |

790 |

500 |

630 |

24 |

445 |

80 |

555 |

100 |

165 |

|

LS800 |

450 |

630 |

550 |

520 |

135 |

970 |

630 |

800 |

30 |

457.5 |

80 |

650 |

120 |

165 |

|

LS1000 |

560 |

710 |

650 |

630 |

150 |

1190 |

710 |

1000 |

30 |

435 |

80 |

760 |

140 |

200 |

|

LS1250 |

710 |

800 |

800 |

760 |

170 |

1440 |

800 |

1250 |

30 |

465 |

80 |

910 |

140 |

200 |