-

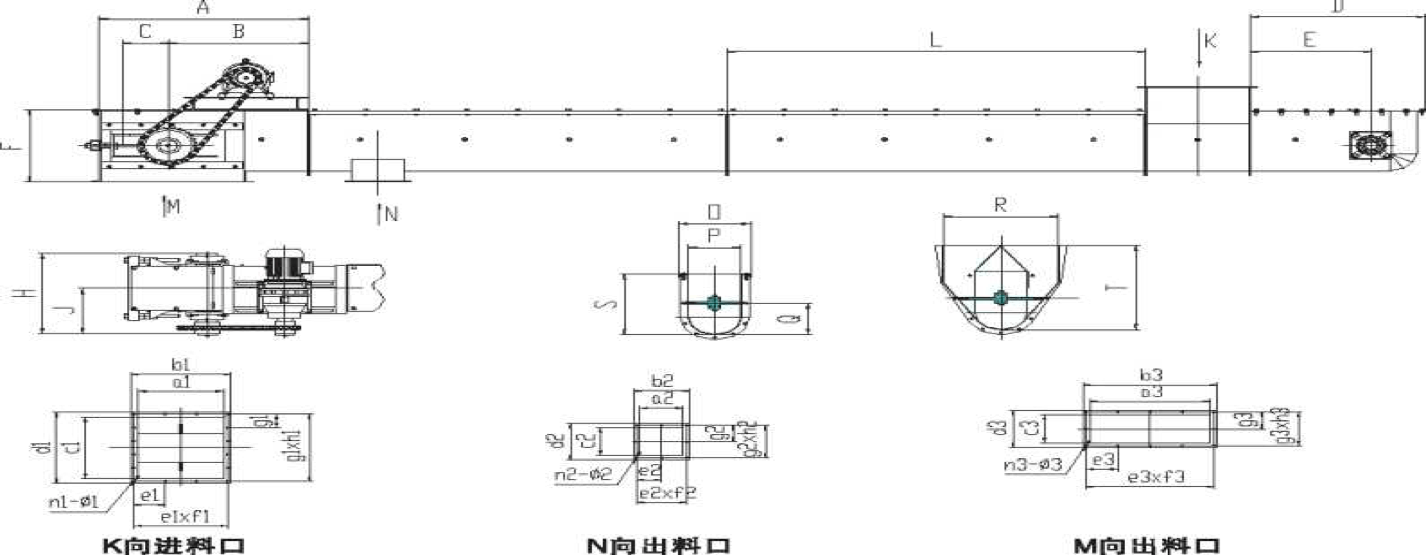

Description & Overall Dimensions Drawing

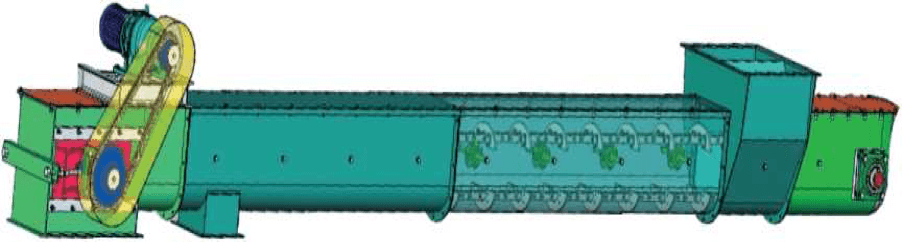

TGSU Self-cleaning(U type) Scraper Conveyor is extensively used in grains,oil,forage,pharmacy,distillery plant for granules and powder in long-distance transportation,installtion angle ≤15° 。

TGSU Self-cleaning(U type) Scraper

description1

Zipper closure

1/5 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the

body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them

in

place during workout

Features

Features:

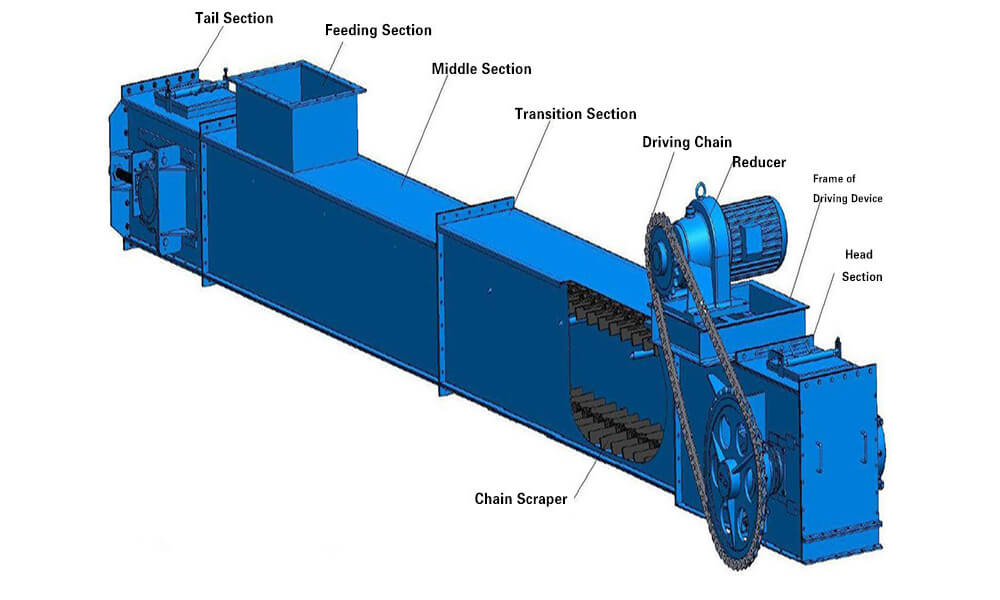

1. Design: The scraper conveyor is designed according to absorb advanced technology from abroad and our many years experience to optimization ;

2.Chain of Conveying: The chain is used high-strength welded chain, because its pins and chain boards are treated specially,so it’s highly strength and wear-resistance strongly.

3.Scraper is made of UHMWPE,when the conveying material tempture under 80℃,It is wear-resisting,impact-resistance,anti high tempture and others advanges.

4. it is a nice machine, good sealing, long time operation, lower consumption,mute,they can auto-compensate between scraper and shell to clear itsselft.

5. installation and maintenance: it is simple structure, easy installation.

6.Safety protection: The tail is installed with stall sensor and the head is installed with material blocking sensor;

Main Parameters

| model | capacity M³/hour | effective section | speed | pitch(mm) | max conveying distance (meter) |

| (M²) | (m/s) | ||||

| TGSU16 | 34 | 0.018 | 0.3~0.8 | 66.25 | ≤80 |

| TGSU20 | 48 | 0.0255 | 0.3-0.8 | 66.25 | ≤80 |

| TGSU25 | 75 | 0.04 | 0.3-0.8 | 66.25 | ≤80 |

| TGSU32 | 149 | 0.079 | 0.3-0.8 | 66.25 | ≤80 |

| TGSU40 | 183 | 0.097 | 0.3~0.8 | 66.25 | ≤60 |

Overall Dimensions Drawing:

Main Dimensions

| model | TGSU16 | TGSU20 | TGSU25 | TGSU32 | TGSU40 |

| A | 750 | 750 | 820 | 892 | 1000 |

| B | 380 | 390 | 420 | 456 | 475 |

| C | 130 | 130 | 130 | 160 | 180 |

| D | 384 | 406 | 428 | 650.5 | 637 |

| E | 220 | 220 | 230 | 380 | 350 |

| F | 313 | 285 | 423 | 585 | 606 |

| G | 445 | 455 | 485 | 536 | 565 |

| H | 388 | 446 | 555 | 727 | 767 |

| J | 224 | 260 | 330 | 418.5 | 438.5 |

| L | 2000 | 2000 | 2000 | 2000 | 2000 |

| 0 | 240 | 280 | 330 | 449 | 472 |

| P | 160 | 200 | 250 | 335 | 372 |

| Q | 140 | 155 | 200.7 | 282.5 | 231 |

| R | 220 | 500 | 500 | 520 | 600 |

| S | 251 | 288 | 341 | 460.5 | 478 |

| T | 360 | 412 | 510 | 673.5 | 680 |

| a1 | 220 | 400 | 500 | 520 | 600 |

| b1 | 280 | 460 | 580 | 600 | 690 |

| c1 | 220 | 500 | 500 | 520 | 600 |

| d1 | 280 | 560 | 580 | 600 | 690 |

| e1 | 125 | 107.5 | 108 | 112 | 129 |

| f1 | 2 | 4 | 5 | 5 | 5 |

| g1 | 125 | 106 | 108 | 112 | 129 |

| h1 | 2 | 5 | 5 | 5 | 2 |

| n1- Φ1 | 8- Φ9 | 18- Φ9 | 20- Φ9 | 20- Φ12 | 20- Φ12 |

| a2 | 250 | 300 | 410 | 450 | 600 |

| b2 | 160 | 200 | 250 | 335 | 372 |

| c2 | 226 | 360 | 480 | 530 | 690 |

| d2 | 316 | 260 | 320 | 415 | 462 |

| e2 | 145 | 110 | 150 | 122.5 | 129 |

| f2 | 2 | 3 | 3 | 4 | 5 |

| g2 | 100 | 115 | 145 | 125 | 104 |

| h2 | 2 | 2 | 2 | 3 | 4 |

| n2- Φ2 | 8- Φ10 | 1O- Φ9 | 10- Φ10 | 14- Φ12 | 18- Φ12 |

| a3 | 550 | 550 | 620 | 672 | 800 |

| b3 | 160 | 200 | 250 | 335 | 372 |

| c3 | 618 | 620 | 690 | 758 | 890 |

| d3 | 228 | 270 | 322 | 421 | 462 |

| e3 | 147.5 | 147.5 | 165.5 | 144 | 170 |

| f3 | 4 | 4 | 4 | 5 | 5 |

| g3 | 100 | 120 | 146 | 126 | 140 |

| h3 | 2 | 2 | 2 | 3 | 3 |

| n3— Φ3 | 12- Φ10 | 12- Φ9 | 12- Φ9 | 16- Φ12 | 16- Φ12 |