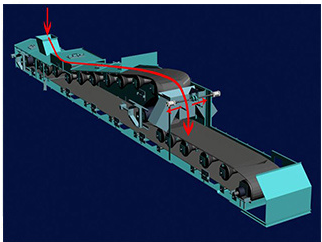

Full sealed backthrowing type multi-point discharge belt conveyor

Working principle and application scenarios:

The back throwing multi-point unloading belt conveyor achieves multi-point unloading through the back throwing intermediate unloader. The unloader consists of upper and lower reversing rollers and a self controlled flipping mechanism, which can unload at multiple points. It is suitable for scenarios that require multi-point unloading, such as port terminals, large grain depots, etc

Comparison with other types of belt conveyors:

Compared with other types of belt conveyors, the throw back multi-point discharge belt conveyor has the following advantages:

- High flexibility: It can flexibly receive materials from one or more points according to the requirements of the process flow, and can also unload materials to multiple points or several sections

- High safety: with high safety and low accident rate

- Low maintenance cost: Due to the use of a fully sealed design, dust emissions are reduced, resulting in lower maintenance cost

The back throwing multi-point discharge belt conveyor has the following characteristics:

- Dustproof and rainproof design: The overall appearance of the machine adopts a dust-proof and rainproof design, with good sealing performance, which can effectively prevent dust from rising outside

- Double cone bearing idler: Adopting double cone bearing idler with external idler bearings for easy maintenance, upkeep, and replacement

- Return throwing intermediate unloader: The return throwing intermediate unloader consists of upper and lower reversing rollers and a self controlled flipping mechanism, which is safe and reliable in operation, and has flexible and convenient process layout

- Micro pressure chamber bearing: The return belt is carried by a micro pressure chamber, which is energy-saving and aesthetically pleasing. It can also be in the form of a pallet or wear-resistant plate

- Energy saving and environmental protection: The fully sealed design reduces dust emissions and meets environmental requirements

- Widely applicable: mainly suitable for industries such as port terminals, large grain depots, oil and fat, corn deep processing, flour processing, etc

| Model | QD650 | QD800 | QD1000 | QD1200 | QD1400 | QD1600 | QD1800 |

| Rated conveying capacity(t/h) | 100-200 | 200-300 | 300-600 | 600-800 | 800-1200 | 1200-1500 | 1500-2000 |

| Belt width(mm) | 650 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 |

| Belt speed(m/s) | 1.25~4 | 1.25~4 | 1.25~4 | 1.25~4 | 1.25~4 | 1.25~4 | 1.25~4 |

Note:The conveying capacity in this table is calculated based on the physical propertirs of the grain(bluk density:0.72).Transporting other materials requires separated calculations based on the physical properties of the material and the on-site process characteristics.

The fully sealed throw back multi-point discharge belt conveyor is currently mainly focused on the port terminal, large grain storage, oil and fat, corn deep processing, and flour processing industries. It mainly consists of a head and tail frame, a driving device, a load-bearing bracket, a conveyor belt, a tensioning mechanism, etc.

Application case 1:Grain conveying system

Application case 2:Grain conveying system