-

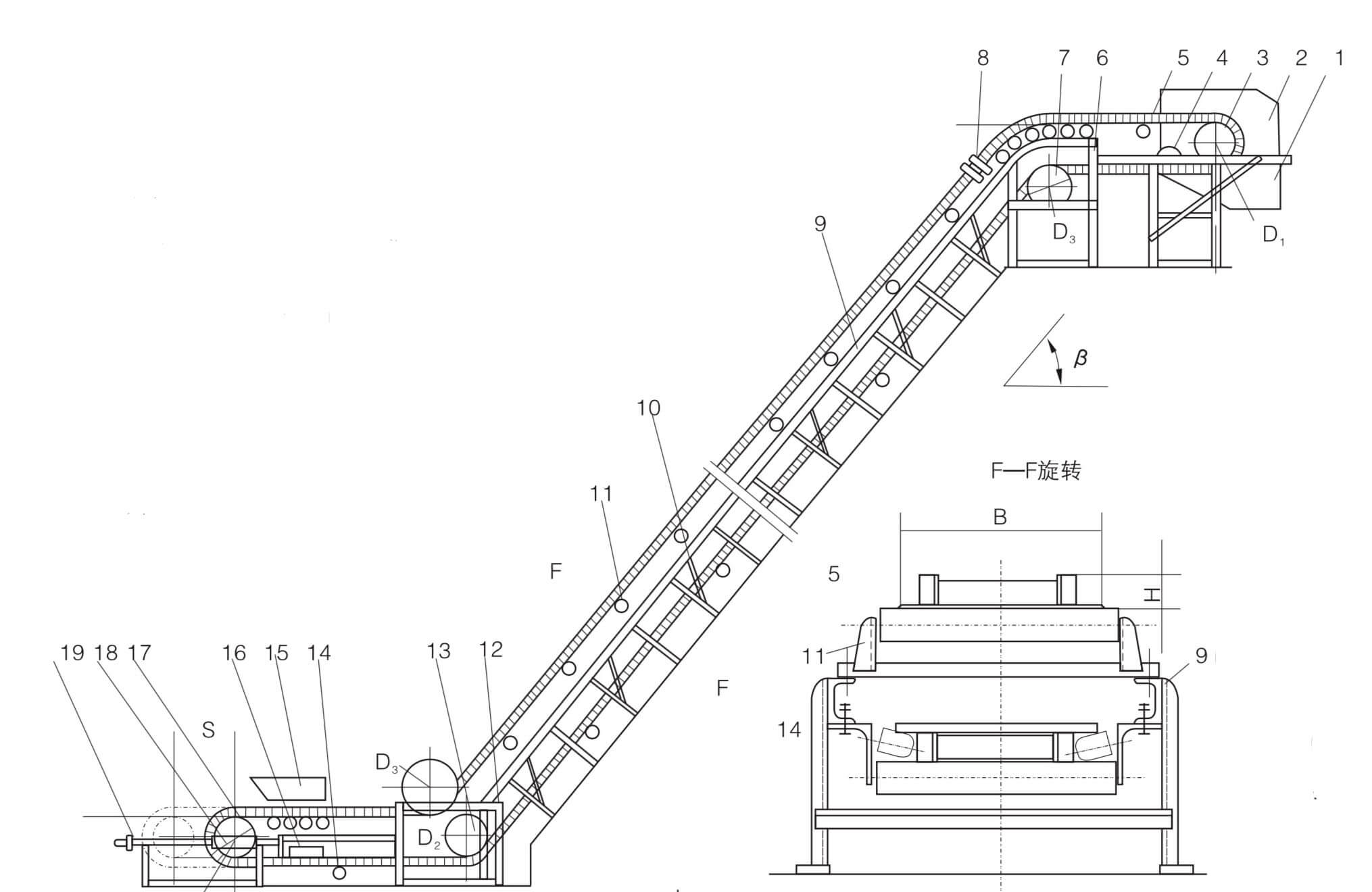

DJ Belt Conveyor With Corrugated Wall

The belt conveyor with corrugated wall and diaphragm has corrugated edge and diaphragmis board, especially be suitable for high angles working. It widely used in coal, chemical industry, The power, building materials, metallurgy, light industry, grain, port and so on, All kinds of bulk materials with bulk density of 0.5 ~ 2.5t/m3 under working temperature from - 15 °C to + 40°C, The maximum conveying capacity is 250M³/H and the maximum particle size is 400mm. The conveying angle of the machine. Within the angle of 0°to 90 °. For special requirements materials, such as high temperature, materials with acid, oil or organic solvent, we consider special conveyor belt with safety precautions.

DJ Belt Conveyor With Corrugated Wall

description1

Zipper closure

1/5 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the

body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them

in

place during workout

FEATURES

The driving device and its combination form of the belt conveyor with wavy edge retaining are suitable for the user's process layout, power selection and other needs:

- A. electric roller (with backstop);

- B. Y series motor + V-belt + shaft mounted reducer,(with backstop) + driving drum;

- C. motor + coupling + reducer + driving drum with backstop

- D. other types of drive

- 1. Discharge bucket

- 2. Head shield

- 3. Drive roller

- 4. Tap the sweeper

- 5. Edge band

- 6. Rack of convex section

- 7. Pressing pulley

- 8. Block rolling

- 9. Middle frame

- 10. Middle frame leg

- 11. Upper roller

- 12. concave screen section frame

- 13. Deflection roller

- 14. Lower supporting roller

- 15. Feeding slot

- 16. Empty section cleaner

- 17. Tail roller

- 18. Tension device

- 19 tailstock

MAIN PARAMETERS

Corrugated sidewall inclined belt conveyor for lage angle Main Technical Parameters

|

Inclination angle |

Sidewallheight(mm) |

80 |

100 |

120 |

160 |

200 |

240 |

300 |

400 |

|

30° |

Capacity |

75-150 |

115-236 |

165-340 |

293-439 |

302-506 |

435-650 |

652-866 |

1015-1157 |

|

35° |

73-166 |

92-235 |

158-307 |

251-376 |

259-470 |

373-614 |

580-830 |

940-1110 |

|

|

40° |

67-144 |

106-216 |

136-288 |

218-346 |

340-432 |

323-575 |

505-700 |

803-1070 |

|

|

45° |

46-126 |

89-196 |

118-267 |

188-365 |

299-457 |

283-535 |

444-646 |

783-1006 |

|

|

50° |

45-111 |

71-173 |

93-245 |

175-336 |

271-420 |

377-564 |

311-585 |

691-982 |

|

|

55° |

65-98 |

77-153 |

120-221 |

158-305 |

251-380 |

335-570 |

343-520 |

610-880 |

|

|

60° |

71-109 |

88-136 |

128-246 |

172-339 |

258-426 |

248-614 |

383-581 |

681-1032 |

|

|

65° |

71-98 |

88-154 |

128-223 |

172-307 |

234-386 |

248-558 |

348-526 |

618-936 |

|

|

70° |

58-89 |

72-140 |

105-201 |

189-279 |

227~350 |

308-502 |

321-630 |

560-849 |

|

|

75° |

52-80 |

79-126 |

96-182 |

132-250 |

199-314 |

107-454 |

289-505 |

503-762 |

|

|

80° |

46-72 |

71-117 |

84-163 |

145-225 |

171-282 |

246-407 |

255-507 |

311-621 |

|

|

85° |

40-64 |

65-104 |

72-144 |

97-199 |

161-260 |

221-359 |

235768 |

236-485 |

|

|

90° |

36-55 |

55-87 |

65-126 |

86-174 |

135-217 |

193-316 |

198-390 |

215-430 |