-

Description & Overall Dimensions Drawing

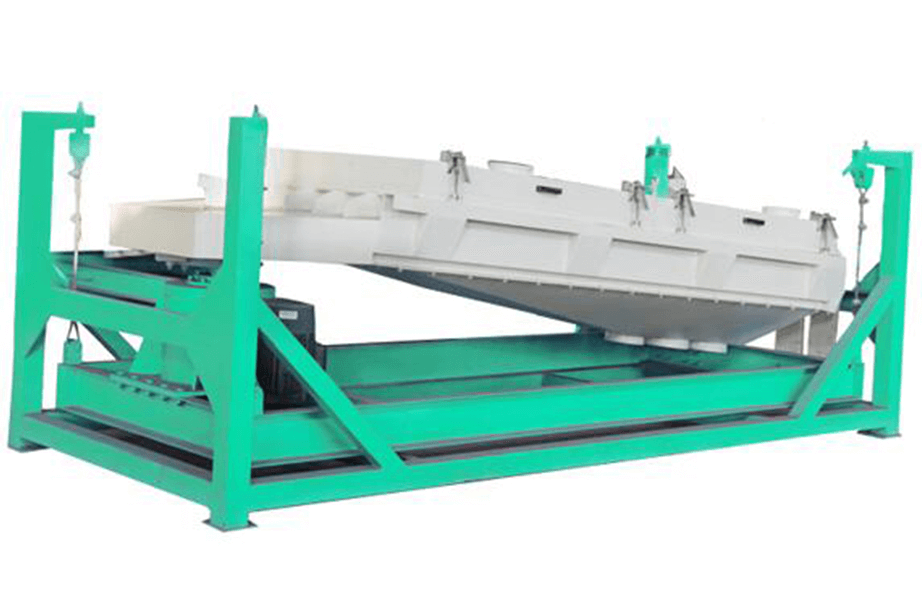

Rotary vibration separation sieve is used for the selection and classification for powder or granular materials. It can also be used for the initial choosing of raw materials and separation of intermediate products after secondary crushing stuffs. Therefore, it can be extensively used in feed,grain,chemical,food,sugar,paper and other industries for screening and grading.

It has inlet for feeding material intensively,Under the action of the circular motion of the screen,which stday on screen surface via automatic classification, keep the smaller materials passed the screen,thus bigger ones goes to opening,because there is no agitation and vertical beating in the moving, the smaller particles are always close to screen and can drop at any time,At outlet point,The screen machine is working repetitive movements making stuff more than screen size of hole go to outlet direction until go out,do the full screening.The ball can't moving,prevent stuff blocking the screen,improve working efficiency,The large and small balance substance keep the inertia force balance,ensuring sieve moving stably.

Rotary Vibration Separation Sieve518628

|

Details |

SFJH71X2 |

SFJH100X2 |

SFJH100X3 |

|

|

sieve length |

1600 |

2140 |

2140 |

|

|

sieve width |

710 |

1000 |

1000 |

|

|

radius of gyration |

30 |

30 |

30 |

|

|

velocity (r/min) |

260 |

260 |

260 |

|

|

kilowatt |

1.1 |

1.5 |

2.2 |

|

|

layers of sieve |

2 |

2 |

2 |

|

|

screen angle |

4°~5° |

4°~5° |

4°~5° |

|

|

capacity |

Material |

5~7 |

8~10 |

10~12 |

|

Ton/hour |

pellets |

8~12 |

12~18 |

15~20 |

|

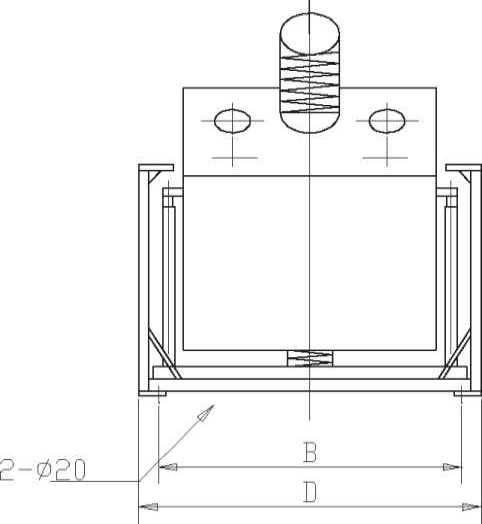

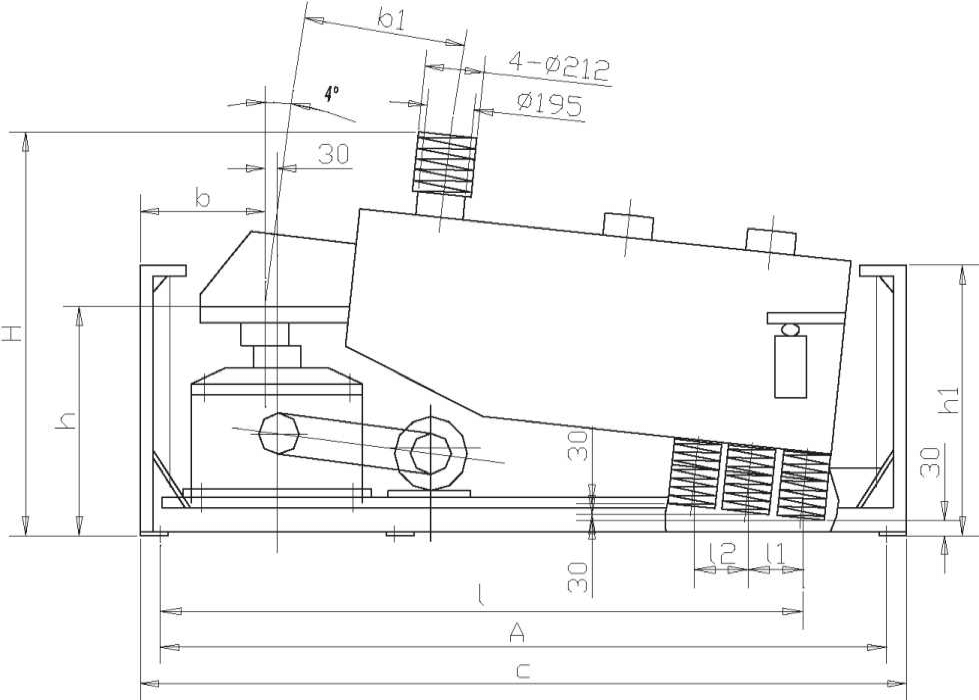

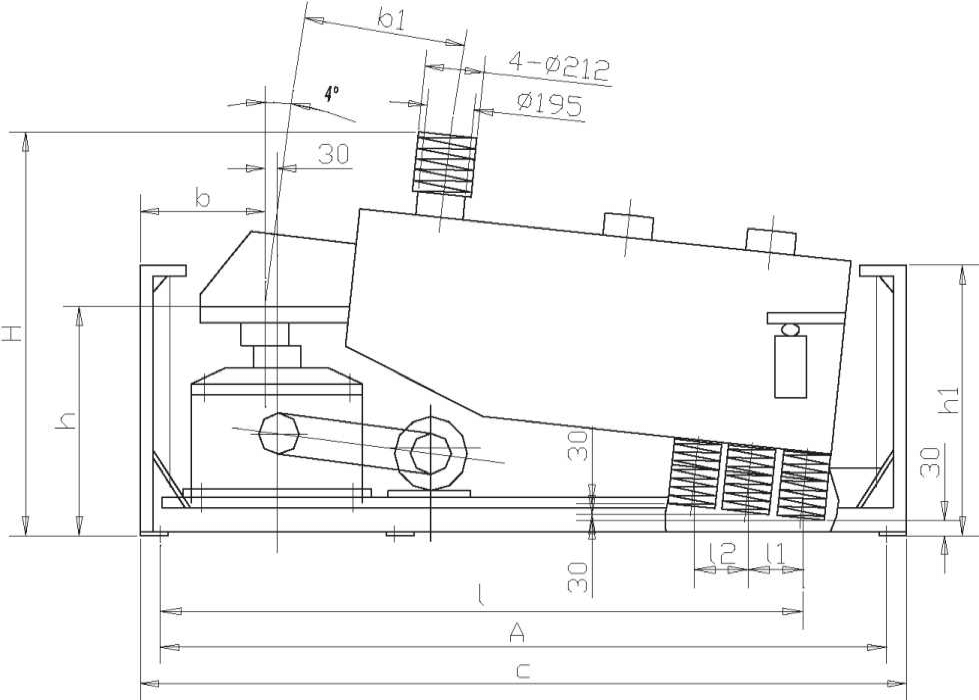

Details Model |

A |

B |

C |

D |

I |

l1 |

l2 |

l3 |

b |

b1 |

H |

h |

h1 |

|

SFJH71X2 |

2560 |

926 |

2780 |

1146 |

2255 |

270 |

250 |

— |

373 |

337 |

1320 |

768 |

876 |

|

SFJH100X2 |

3100 |

1210 |

3320 |

1430 |

2795 |

270 |

250 |

— |

373 |

337 |

1360 |

768 |

916 I |

|

SFJH100X3 |

3100 |

1210 |

3320 |

1430 |

2795 |

190 |

190 |

190 |

373 |

337 |

1400 |

768 |

916 |